Technicial Specifications

| Net Power - ISO 9249 | 252 HP 185 kW |

| Emissions | Tier 3/Stage IIIA Tier 3/Stage IIIA |

| Maximum Gross Power - 2,000 rpm - ISO 14396 - Metric | 195 kW (265 hp) 195 kW (265 hp) |

| Maximum Net Power - 2,000 rpm - ISO 9249 - Metric | 185 kW (252 hp) 185 kW (252 hp) |

| Peak Gross Torque - 1,400 rpm - ISO 14396 | 774 lb/ft 1050 N·m |

| Displacement | 428 in³ 7.01 l |

| Engine Model | Cat C7.1 Cat C7.1 |

| Maximum Net Torque - 1,400 rpm | 726 lb/ft 984 N·m |

| Operating Weight | 39983 lb 18136 kg |

| Note | Weight based on a machine configuration with Michelin 23.5R25 XHA2 L3 radial tires, full fluids, operator, standard counterweight, cold start, roading fenders, Product Link™, open/open axles (front/rear), power train guard, secondary steering, sound suppression and a 3.1 m³ general purpose bucket with BOCE. Weight based on a machine configuration with Michelin 23.5R25 XHA2 L3 radial tires, full fluids, operator, standard counterweight, cold start, roading fenders, Product Link™, open/open axles (front/rear), power train guard, secondary steering, sound suppression and a 3.1 m³ general purpose bucket with BOCE. |

| Bucket Capacities | 2.7-4.4 m³ (3.5-5.8 yd³) 2.7-4.4 m³ (3.5-5.8 yd³) |

| Static Tipping Load - Full 40° Turn - With Tire Deflection | 24088 lb 10926 kg |

| Breakout Force | 34171 lbf 152 kN |

| Static Tipping Load - Full 40° Turn - No Tire Deflection | 25627 lb 11624 kg |

| Note (1) | For a machine configuration as defined under "Weight." For a machine configuration as defined under "Weight." |

| Note (2) | Full compliance to ISO 143971:2007 Sections 1 thru 6, which requires 2% verification between calculations and testing. Full compliance to ISO 143971:2007 Sections 1 thru 6, which requires 2% verification between calculations and testing. |

| Forward - 4 | 16 mile/h 25.7 km/h |

| Reverse - 1 | 4.3 mile/h 6.9 km/h |

| Reverse - 2 | 7.5 mile/h 12 km/h |

| Reverse - 3 | 16 mile/h 25.7 km/h |

| Forward - 3 | 12 mile/h 19.3 km/h |

| Forward - 1 | 4.3 mile/h 6.9 km/h |

| Forward - 2 | 7.5 mile/h 12 km/h |

| Note | Maximum travel speed in standard vehicle with empty bucket and standard L3 tires with 787 mm roll radius. Maximum travel speed in standard vehicle with empty bucket and standard L3 tires with 787 mm roll radius. |

| Forward - 5 | 24.5 mile/h 39.5 km/h |

| Implement Pump Type | Variable Axial Piston Variable Axial Piston |

| Implement System - Maximum Pump Output at 2,340 rpm | 64.7 gal/min 245 l/min |

| Hydraulic Cycle Time - Total | 9.5 s 9.5 s |

| Implement System - Maximum Operating Pressure | 4047 psi 27900 kPa |

| Cooling System | 14.3 gal (US) 54 l |

| Differential - Final Drives - Rear | 11.4 gal (US) 43 l |

| Differential - Final Drives - Front | 11.4 gal (US) 43 l |

| Fuel Tank | 72.6 gal (US) 275 l |

| Crankcase | 5.3 gal (US) 20 l |

| Transmission | 11.4 gal (US) 43 l |

| Hydraulic Tank | 33 gal (US) 125 l |

| With Cooling Fan Speed at Maximum Value - Operator Sound Pressure Level (ISO 6396:2008) | 72 dB(A) 72 dB(A) |

| With Cooling Fan Speed at Maximum Value - Exterior Sound Pressure Level (SAE J88:2013) | 75 dB(A)* 75 dB(A)* |

| With Cooling Fan Speed at Maximum Value - Exterior Sound Power Level (ISO 6395:2008) | 107 dB(A) 107 dB(A) |

| With Cooling Fan Speed at 70% of Maximum Value - Exterior Sound Power Level (ISO 6395:2008)** | 104 LWA*** 104 LWA*** |

| With Cooling Fan Speed at 70% of Maximum Value - Operator Sound Pressure Level (ISO 6396:2008)** | 69 dB(A) 69 dB(A) |

| Note (3) | ***European Union Directive 2000/14/EC as amended by 2005/88/EC. ***European Union Directive 2000/14/EC as amended by 2005/88/EC. |

| Note (1) | *Distance of 15 m, moving forward in second gear ratio. *Distance of 15 m, moving forward in second gear ratio. |

| Note (2) | **For machines in countries that adopt the EU Directives. **For machines in countries that adopt the EU Directives. |

| Centerline of Rear Axle to Edge of Counterweight | 6.83 ft 2083 mm |

| Overall Length - Without Bucket | 22.77 ft 6939 mm |

| Hinge Pin Height at Maximum Lift | 13.11 ft 3995 mm |

| Ground Clearance | 1.21 ft 368 mm |

| Hinge Pin Height at Carry Height | 2.18 ft 663 mm |

| Height - Top of ROPS | 11.33 ft 3446 mm |

| Tread Width | 7 ft 2140 mm |

| Rack Back - Carry Height | 49 degrees 49 degrees |

| Height - Top of Hood | 8.83 ft 2697 mm |

| Note | All dimensions are approximate and based on Michelin 23.5R25 XHA2 L3 radial tires. All dimensions are approximate and based on Michelin 23.5R25 XHA2 L3 radial tires. |

| Rack Back - Maximum Lift | 60 degrees 60 degrees |

| Wheel Base | 11 ft 3350 mm |

| Rack Back at Ground | 41 degrees 41 degrees |

| Maximum Width - Over Tires - Loaded | 9.33 ft 2822 mm |

| Centerline of Rear Axle to Hitch | 5.5 ft 1675 mm |

| Lift Arm Clearance at Maximum Lift | 11.19 ft 3410 mm |

| Height - Top of Exhaust Pipe | 11.2 ft 3415 mm |

| Height - Top of ROPS | 11.33 ft 3446 mm |

| Height - Top of Hood | 8.83 ft 2697 mm |

| Centerline of Rear Axle to Edge of Counterweight | 6.83 ft 2071 mm |

| Centerline of Rear Axle to Hitch | 5.5 ft 1675 mm |

| Rack Back at Ground | 45 degrees 45 degrees |

| Hinge Pin Height at Carry Height | 2.51 ft 765 mm |

| Lift Arm Clearance at Maximum Lift | 12.45 ft 3794 mm |

| Wheel Base | 11 ft 3350 mm |

| Tread Width | 7 ft 2140 mm |

| Rack Back - Maximum Lift | 66 degrees 66 degrees |

| Overall Length - Without Bucket | 24.37 ft 7428 mm |

| Rack Back - Carry Height | 54 degrees 54 degrees |

| Height - Top of Exhaust Pipe | 11.2 ft 3415 mm |

| Ground Clearance | 1.21 ft 368 mm |

| Maximum Width - Over Tires - Loaded | 9.33 ft 2822 mm |

| Note | All dimensions are approximate and based on Michelin 23.5R25 XHA2 L3 radial tires. All dimensions are approximate and based on Michelin 23.5R25 XHA2 L3 radial tires. |

| Hinge Pin Height at Maximum Lift | 14.73 ft 4490 mm |

| Emissions | Tier 3/Stage IIIA Tier 3/Stage IIIA |

| Bucket Range | 2.7-4.4 m³ (3.5-5.8 yd³) 2.7-4.4 m³ (3.5-5.8 yd³) |

Advantages and Features

RELIABILITY YOU CAN COUNT ON

- Cat® C7.1 engine offers a combination of proven electronic, fuel, and air systems.

- Utilizing rigorous component design and machine validation processes results in unmatched reliability, durability and high uptime.

LONG TERM VALUE AND DURABILITY

- Tough countershaft powershift transmission and axles handle extreme applications.

- Improved hydraulic hose routing reduces potential hose wear.

- Full flow hydraulic filtration system with additional loop filtration improves hydraulic system robustness and component life.

BUILT TO PERFORM

- Engine power increased by approximately 22% improves machine performance and response (compared to H Series).

- Lock-up clutch torque converter, combined with lock-to-lock shifting, delivers smooth shifts, fast acceleration and speed on grade.

- High capacity torque converter results in greater digging efficiency.

- Z-bar linkage provides high breakout force at ground level.

- Optional high lift linkage offers increased hinge pin height to load more easily in a variety of applications.

- Easy-to-load Performance Series Buckets feature a wider mouth and curved side plates that improve material retention (fill factor) and decrease cycle times.

- Optional fully automatic traction control system (differential locks) improves performance in the pile and poor underfoot conditions.

DO MORE WITH LESS FUEL

- Up to 10% lower fuel consumption than H Series.*

- Power dense engine burns less fuel by providing power and torque when needed.

- Performance Series Buckets feature a longer floor that easily digs through the pile resulting in lower fuel consumption.

- Load sensing hydraulics result in proportional flow for implement and steering on demand.

- Standard productive Economy Mode provides maximum fuel savings with minimal productivity impact.

* Actual results may vary based on factors such as, but not limited to, machine configuration, operator technique, machine application, climate, etc.

DESIGNED FOR OPERATORS

- New best-in-class operator environment provides unmatched comfort, visibility, and efficiency.

- Intuitive, ergonomic controls keep operators focused on their work.

- Optional new ride control system with dual accumulators provides excellent ride quality and lowers cab vibrations.

ENSURING A SAFE JOB SITE

- Excellent cab access with wide door and stair-like steps.

- Floor to ceiling windshield, large mirrors with integrated spot mirrors and rear vision camera provide industry leading all-around visibility.

- Robust, repositioned grab bars provide safe access to platforms.

SAVE ON SERVICE AND MAINTENANCE

- One-piece tilting hood with side and rear doors; hydraulic and electrical service centers make access fast and easy.

- Safe ground level access to fuel fill, oil fill, filters and daily maintenance points means less servicing time required.

- Optional, fully integrated Cat Autolube system provides full lube system monitoring and diagnostic test visibility.

TECHNOLOGY THAT GETS WORK DONE

- Monitor, manage and enhance job site operations.

- Cat LINK Technologies: VisionLink® enables owners to access data wirelessly to monitor machine health, utilization and location.

- Cat DETECT Technologies: Integrated rear vision camera enhances visibility behind machine to help operators work safely. Optional Cat Rear Object Detection increases operator awareness of the working environment which enhances site safety.

- Cat PAYLOAD Technologies: Optional Cat Production Measurement 2.0 brings simple and accurate on-the-go payload scale allowing operators to deliver exact loads and work more efficiently. Advanced Productivity subscription provides comprehensive actionable information to help you manage and improve the productivity and profitability of your operations.

Standard Equipment

-

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

POWER TRAIN

- Engine, Cat C7.1 meets China Nonroad Stage III and India Bharat Stage III emission standards, equivalent to Tier 3 and Stage IIIA

- Fuel priming pump (electric)

- Fuel/water separator

- Rain caps, engine air intake

- Economy Mode (selectable)

- Transmission, automatic countershaft power shift (5F/3R)

- Torque converter, locking clutch with free wheel stator

- Switch, transmission neutralizer lockout

- Axles, open differential front and rear axles

- Brakes, full hydraulic enclosed wet-disc with Integrated Braking System (IBS)

- Brake wear indicators

- Parking brake, disc and caliper

- Fan, radiator, electronically controlled, hydraulically driven, temperature sensing, on demand

-

OPERATOR ENVIRONMENT

- Cab, pressurized and sound suppressed (ROPS/FOPS)

- Viscous mounts

- Rear vision camera within multi-funciton 18 cm color LCD touch-screen display (capability for displaying machine status, setting and health parameters)

- EH controls, SAL (single axis lever) lift and tilt function

- Steering wheel

- Radio ready (entertainment) includes antenna, speakers and converter (12V, 10-amp)

- Air conditioner, heater, and defroster

- EH parking brake

- Beverage holders (2) with storage compartment for cell phone/MP3 player

- Bucket/work tool fuction lockout

- Coat hook

- Cab air filter

- Ergonomic cab access ladders and handrails

- Horn, electric

- Light, two dome (cab)

- Mirros, rearview external with integrated spot mirrors

- Post mounted membrane 16 switch keypad

- Two receptacles, 12V

- Seat, Cat Comfort (cloth) air suspension

- Seat belt, 51 mm retractable

- Sun visor, front

- Wet-arm wipers/washers front and rear, intermittent front wiper

- Window, sliding (left and right sides)

-

COMPUTERIZED MONITORING SYSTEM

- With following gauges: Speedometer/tachometer; Digital gear range indicator; Temperature: engine coolant, hydraulic oil, transmission oil; Fuel level

- With following warning indicators: Temperature: axle oil, engine intake manifold; Pressure: engine oil, fuel pressure hi/low, primary steering oil, service brake oil; Battery voltage hi/low; Engine air filter restriction; Hydraulic oil filter restriction; Hydraulic oil low; Parking brake; Transmission filter bypass

-

ELECTRICAL AND LIGHTING

- Batteries (2), maintenance free 1,400 CCA

- Ignition key; start/stop switch

- Starter, electric, heavy duty

- Starting and charging system (24V)

- Lighting system: Four halogen work lights (cab mounted); Two LED stop, turn tail lights; Two halogen roading lights (with signals); Two halogen rear avision lights (hood mounted)

- Alarm, back-up

- Alternator, 145-amp brushed

- Main disconnect switch

- Receptacle start (cables no included)

-

CAT CONNECT TECHNOLOGIES

- Link technologies: Product Link

- Detect technologies: rear vision camera

-

LINKAGE

- Linkage, Z-bar, cast crosstube/tilt lever

- Kickout, lift and tilt, automatic (adjustable in cab)

-

HYDRAULICS

- Hydraulic system, load sensing

- Steering, load sensing

- 2V

- Remote diagnostic pressure taps

- Hoses, Cat XT

- Couplings, Cat O-ring face seal

- Hydraulic oil cooler (swing out)

- Oil sampling valves

-

FLUIDS

- Premixed extended life coolant with freeze protection to -34 degrees C

-

OTHER STANDARD EQUIPMENT

- Hood, non-metallic power tilting

- Service centers (electrical and hydraulic)

- Auto idle shutdown

- Fenders

- Ecology drains for engine, transmission, and hydraulics

- Grill, airborne debris

- Filters: fuel, engine air, engine oil, hydraulic oil, transmission

- Grease zerks

- Hitch, drawbar with pin

- Precleaner rain cap

- Sight gauges: engine coolant, hydraulic oil, and transmission oil level

- Toolbox

- Vandlism protection caplocks

Optional Equipment

-

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

-

POWER TRAIN

- Axles: Automatic front/rear differential locks; Axle oil cooler; Ecology drains; Extreme temperature seals/ Seal guards

- Fan, VPF (variable pitch fan), automatic and manual control

- Radiator, high debris with wider fin spacing

-

OPERATOR ENVIRONMENT

- Cab tie-off

- Cover, HVAC metallic

- EH controls, SAL 3rd function

- EH controls, joystick lift and tilt - Additional integrated roller switches for 3rd function

- Filter, carbon fresh air

- Mirrors, heated rearview external with integrated spot mirrors

- Precleaner, HVAC

- Radio, AM/FM/CD/USB/MP3 Bluetooth

- Radio, CB ready

- Seat, heated air suspension

- Seat belt, 76 mm retractable

- Roof, metallic

- Steering, secondary

- Sun visor, rear

- Windows, rubber mounted

- Windows, with front guard

- Windows, with full guards front, rear and sides

-

ELECTRICAL AND LIGHTING

- Four additional auxiliary halogen cab mounted work lights or

- Two additional auxiliary front HI LED and two additional auxiliary rear LED cab mounted work lights with two LED work lights in the radiator grill and LED front turn signals also includes replacement of the standard four halogen cab mounted work lights with four LED work lights (the standard offering and only roading light available is the halogen roading light)

- Warning amber strobe beacon

- Reversing strobes

-

STARTERS, BATTERIES, AND ALTERNATORS

- Cold start - 120V

- Cold start - 240V

-

CAT CONNECT TECHNOLOGIES

- Link technologies: VIMS

- Payload technologies: Cat Production Measurement 2.0 (Cat payload system); Printer, Cat Production Measurement; Aggregate Autodig

- Productivity: Cat Advanced Productivity (optional VisionLink subscription add-on for Cat Production Measurement 2.0)

- Detect technologies: Cat Rear Object Detection

- Machine Security System

-

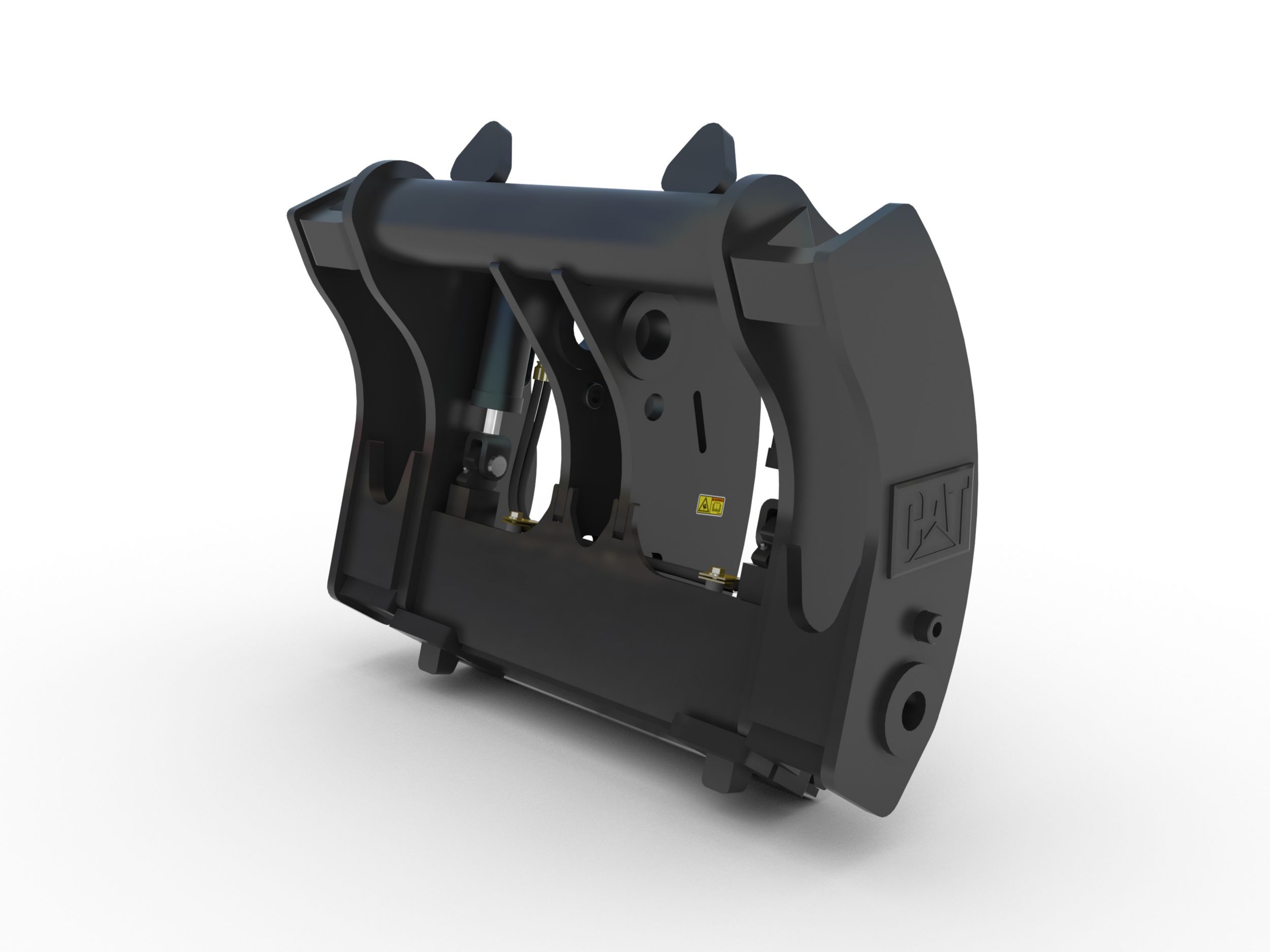

LINKAGE

- High lift

- Forestry

- Quick coupler ready

- Autolube

-

WORK TOOLS

- Performance Series buckets

- Fusion quick coupler

- Forks, pallet

- Forks, logging

-

HYDRAULICS

- Ride control

- 3rd function with Ride Control: Standard linkage; High lift linkage; Forestry linkage

-

FLUIDS

- Premixed extended life coolant with freeze protection to -50° C

-

OTHER OPTIONAL EQUIPMENT

- Cat Autolube System

- Fenders, roading

- Guard, power train

- Precleaner, turbine

- Precleaner, trash

- Platform, window washing

- Cold weather package: Transmission filter bypass; Fan pump bypass; Jacket water or engine block heater; Ether aid ready

-

OPTIONAL APPLICATION SPECIFIC CONFIGURATIONS

- Industrial and Waste Handler

- Steel Mill

- Corrosion Resistance