Teknik Özellikler

| Yedek Güç Değeri | 2.750 ekW 2.750 ekW |

| Birincil Güç Değerleri | 2.500 ekW 2.500 ekW |

| Emisyonlar/Yakıt Stratejisi | Tier 2, Düşük NOx Tier 2, Düşük NOx |

| Voltaj | 416 - 13.800 volt 416 - 13.800 volt |

| Frekans | 60 Hz 60 Hz |

| Hız | 1.800 dev/dk. 1.800 dev/dk. |

| Hizmet Çevrimi | Yedek, Görev Açısından Kritik, Birincil Yedek, Görev Açısından Kritik, Birincil |

| Maksimum Değer | 2.750 ekW 2.750 ekW |

| Minimum Değer | 2.500 ekW 2.500 ekW |

| Motor Modeli | 3516E, V-16, 4 Zamanlı, Su Soğutmalı Dizel 3516E, V-16, 4 Zamanlı, Su Soğutmalı Dizel |

| İç Çap | 6.69 inç 170 mm |

| Strok | 8.47 inç 215 mm |

| Silindir Hacmi | 4765 in³ 78.1 l |

| Sıkıştırma Oranı | 14.7:1 14.7:1 |

| Havalandırma | ATAAC ATAAC |

| Yakıt Sistemi | EUI EUI |

| Regülatör Tipi | ADEM™ A5 ADEM™ A5 |

| Uzunluk - Maksimum | 311.9 inç 7922 mm |

| Genişlik - Maksimum | 104 inç 2640 mm |

| Yükseklik - Maksimum | 131.6 inç 3342 mm |

| Kuru Ağırlık - Jeneratör Seti (maksimum) | 40750 lb 18480 kg |

Avantaj ve Özellikler

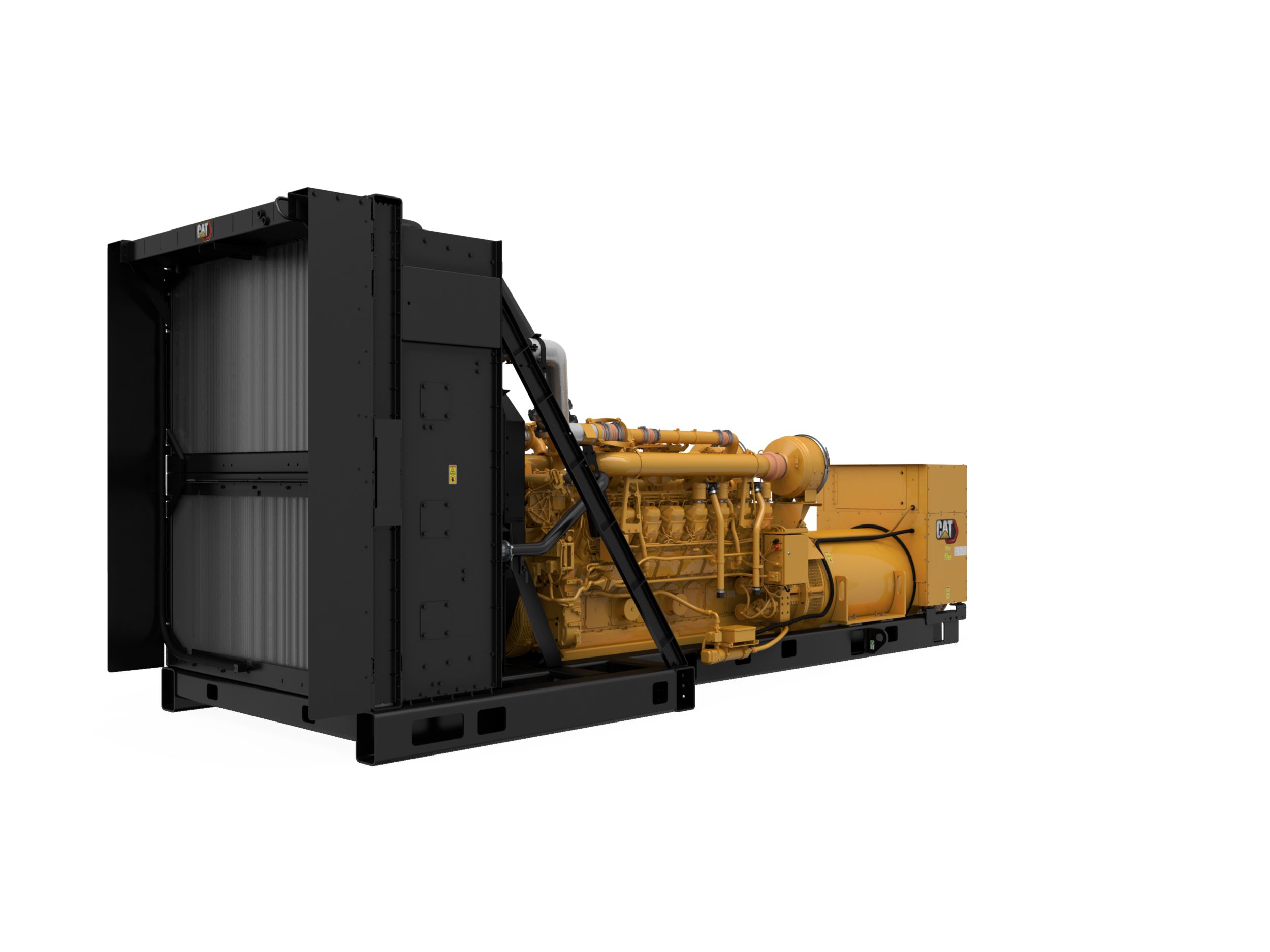

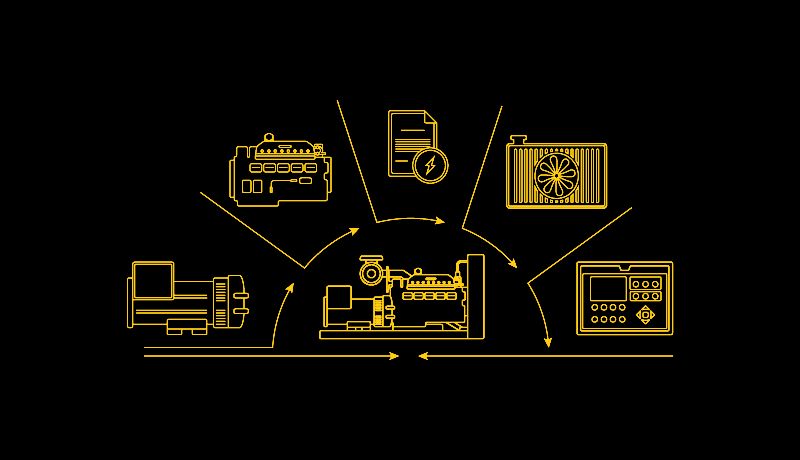

Cat Jeneratör Seti Ünitesi

- Cat jeneratör seti paketleri, prototip aşamasında tamamen test edilmiştir

- Tek adımda %100 blok yükü kabul eder ve diğer NFPA 110 yükleme gereksinimlerini karşılar

- ISO 8528-5 kararlı durum ve geçici tepki standartlarına uyar

Cat Dizel Motor

- Güvenilir, sağlam ve dayanıklı tasarım

- Dünya genelinde sahada binlerce uygulamayla kanıtlanmıştır

- Dört zamanlı dizel motor, tutarlı performans ve mükemmel yakıt tasarrufunu minimum ağırlık ile birleştirir

SR5 Alternatör

- Üstün motor başlatma özelliği, alternatör boyutunu büyütme gereğini en aza indirir

- Cat dizel motorların performansına ve çıkış özelliklerine uygun olarak tasarlanmıştır

- Sağlam H Sınıfı yalıtım

Cat ECS Kontrol Paneli

- Kullanıcı dostu arayüz ve gezinme

- Çok sayıda kurulum gereksinimlerini karşılamak için ölçeklenebilir sistem

- Genişletme modülleri ve spesifik müşteri ihtiyaçları için sahaya özel programlama

Soğutma Sistemi

- 50 °C'ye (122 °F) kadar standart ortam sıcaklıklarında çalışmak üzere tasarlanmıştır

- Belirli ortam sıcaklığı ve rakım değerleri için Cat Temsilcinizle iletişime geçin

Sertifikalar

- UL 2200 Onaylı

- CSA

- IBC deprem sertifikası

- OSHPD ön onaylıdır

Tek Güvenilir Kaynak

- Jeneratör setinde kullanılan komponentler, optimum paket performansı sunmak için tasarım aşamasında seçilir

- Jeneratör setinin tamamı bir Caterpillar tesisinde kalite ilkelerimize uyularak birleştirilmiştir

- Her jeneratör seti paketi, Caterpillar tesisinden ayrılmadan önce test edilir

- Cat ürün desteği; temsilci hizmeti, parça ve garanti dahil olmak üzere tüm Cat güç sistemini kapsar

Dünya Çapında Ürün Desteği

- Cat temsilcileri, 200 ülkede faaliyet gösteren 1.800'den fazla temsilci mağazasına sahiptir

- Yerel Cat temsilciniz, bakım ve onarım anlaşmaları da dahil olmak üzere kapsamlı satış sonrası destek hizmetleri sunmaktadır

Standart Donanımlar

-

Hava Giriş Sistemi

- Tek elemanlı ve servis göstergeli kap

- Hava filtresi

-

Soğutma

- Pakete monte radyatör

-

Egzoz

- Flanşlı egzoz çıkışı

-

Yakıt

- Entegre su ayırıcılı ana yakıt filtresi

- Yakıt besleme pompası

-

Jeneratör

- IP23 Koruması

- Cat motorlarının performans ve çıkış özellikleri ile uyumludur

-

Güç Sonlandırma

- Bara

-

Marş/Şarj

- Ağır hizmet tipi marş sistemi

- Şarj alternatörü

-

Kontrol Paneli

- İletişim:

- 6 Programlanabilir dijital giriş

- Programlanabilir koruyucu röle işlevleri:

- Düşük yağ basıncı

- Çevreden yalıtılmış ön yüz

- Volt (L-L ve L-N)

- Acil durdurma düğmesi

- Seri anonsiyatör modülü veri bağlantısı

- Tersine güç (kW) (32)

- Motor marş çevrimi

- Lamba testi

- Yüksek/düşük frekans (81 y/d)

- kW-sa (toplam)

- Hız ayarı

- True RMS AC ölçümü, 3 faz, +/-%2 doğruluk

- Motor soğuma zamanlayıcısı

- Aşırı akım (50/51)

- Tersine tepkisel güç (kVAr) (32RV)

- kW (faz başına, ortalama ve yüzde)

- kWar-sa (toplam)

- Jeneratör faz sıralaması

- Yağ basıncı (psi, kPa veya bar)

- Düşük soğutucu sıvı sıcaklığı

- Amper (faz başına ve ortalama)

- Jeneratöre monte - arkaya bakan

- Yüksek/düşük voltaj (27/59)

- Düşük soğutucu sıvı seviyesi

- Aksesuar modülü veri bağlantısı

- kVAr (faz başına, ortalama ve yüzde)

- Cat ECS kontrolörü şunları içerir:

- Marş arızası (fazla marş)

- 2 Programlanabilir röle çıkışı (Form C)

- Cat ECS 100

- Aşırı devir

- 2 Programlanabilir dijital çıkış

- DC volt değerleri

- Frekans (Hz)

- Yüksek soğutma sıvısı sıcaklığı

- Aşağıdakiler için ortak LED kapatma göstergeli uyarı/kapatma:

- Çalışma saatleri

- 4 Programlanabilir röle çıkışı (Form A)

- Soğutucu sıvı sıcaklığı

- Güç faktörü (faz başına ve ortalama)

- Aşağıdakiler için dijital gösterim:

- Panel ışıkları

- Metin biçiminde alarm/olay açıklamaları

- Kumandalar:

- 24 Volt DC çalışma

- Alarm kabul etme

- Müşteri veri bağlantısı (Modbus RTU)

- kVA (faz başına, ortalama ve yüzde)

-

Soğutma Sistemi

- Caterpillar uzun ömürlü soğutucu sıvı

- Valfli soğutucu sıvı tahliye hattı

- Soğutma sıvısı seviye sensörleri

- JWAC

- Radyatör fanı ve fan tahrik mekanizması

- Fan ve kayış korumaları

-

Egzoz Sistemi

- Kuru egzoz manifoldu

- Flanşlı çıkışlar

-

Yakıt Sistemi

- İkinci yakıt filtreleri

- Esnek yakıt hatları - gevşek halde teslim edilir

- Yakıt soğutucu, radyatörsüz paketlere dahil değildir

- Yakıt besleme pompası

-

Jeneratörler ve Ataşmanlar

- Form sarılı

- 3 Fazlı fırçasız, Çıkık kutup

- H Sınıfı yalıtım, 40 °C ortam sıcaklığında F Sınıfı sıcaklık yükselmesi (105 °C birincil / 130 °C yedek)

- Sargı sıcaklık detektörleri

- Sabit mıknatıs uyarımı (PMG)

- Yoğuşmasız alan ısıtıcı

- Sağ taraf uzatma kutusu, bara bağlantıları, üstten montaj, alttan kablo girişi

- 6 Uç

- NEMA standart delikli model

-

Regülatör Sistemi

- ADEM III

-

Dokümanlar

- Parça kitabı

- Kullanma ve Bakım Kılavuzu

-

Yağlama Sistemi

- Entegre yağlama yağı soğutucusu

- Duman atığı

- Yağ tahliye sistemi hatları ve valfi

- Yağ filtresi, doldurma kapağı ve seviye çubuğu

- Yağlama yağı

- Dişli tip yağlama yağı pompası

-

Montaj Sistemi

- Titreşim önleyici kauçuk takozlar - takılmamış halde teslim edilir

- Raylar - motor/jeneratör/radyatör montaj tertibatı

-

Marş / Şarj Sistemi

- Akü ayırma anahtarı

- 45 Amper Şarj jeneratörü

- Akü, akü rafı ve kablolar

- 24 Volt elektrikli çalıştırma motoru

-

Genel

- Volan ve volan muhafazası - SAE No. 00

- SAE standart dönüş

- Boya - Çok parlak siyah raylı ve radyatörlü Caterpillar sarısı

- Sağdan servis

İsteğe Bağlı Donanımlar

-

Hava Giriş Sistemi

- Hava girişi koruması

- Uzak hava giriş adaptörleri

- Çift elemanlı hava filtresi

- Ağır hizmet tipi hava filtreleri

-

Çıkış şalterleri

- Bara bağlantıları

- P Frame devre kesici bağlantıları

- R Frame devre kesici bağlantıları

- Opsiyonel bara elektrik bağlantıları

- Devre kesici kablo demetleri

- Masterpack devre kesici bağlantıları

- Kablo giriş seçenekleri

- 2.000, 2.500, 3.200 ve 4.000 Amper, 4 Kutuplu, IEC Sınıfı Devre kesiciler

- 2.000, 2.500, 3.200, 4.000 ve 5.000 Amper, 3 Kutuplu, IEC sınıfı Devre kesiciler

- 1.600, 2.000, 2.500, 3.000, 4.000, 5.000 Amper, 3 Kutuplu, UL-%100 sınıfı Devre kesiciler

-

Güç Sonlandırma

- Devre kesiciler, IEC uyumlu

-

Kontrol Paneli

- Müşteri arayüzü seçenekleri

- Montaj grubu - Harici kutu klipsleri

- EMCP 4.4

- PC ile izleme (Uzaktan ve yerel)

- Topraklama

- Yük paylaşma modülü seçenekleri

- Anonsiyatör modülleri

- Yardımcı kutu

- Dil seçenekleri

- Uzaktan devir ayarı

- Tahribata karşı korumalı panel kapısı

- Voltaj artırma/düşürme anahtarı

- Jeneratör sıcaklığını izleme

-

Soğutma Sistemi

- Genleşme depoları

- Opsiyonel Serpantin radyatörler

- Anahtarlı su seviyesi göstergeleri

- Opsiyonel ATAAC radyatörler

-

Egzoz Sistemi

- Esnek bağlantılar

- Dirsekler

- Flanş ve egzoz bağlantıları

- Flanşlar

- Y Adaptörler

- Susturucular

-

Yakıt Sistemi

- Çift katlı yakıt filtreleri

- Ana yakıt filtreleri

-

Jeneratörler ve eklentiler

- Akım farkı transformatörleri - 8,7 ve 15 kV sınıfı

- Jeneratör hava filtreleri

-

Gösterim

- Yüksek sıcaklık ölçer ve ısıl çiftler

-

Yağlama Sistemi

- Manuel ön yağlama pompası

- Standart karterde yağlama yağı

- Yağ seviyesi regülatörü

- Elektrikli ön yağlama pompaları

-

Montaj Sistemi

- Yaylı tip titreşim yalıtıcıları

- IBC Sismik titreşim yalıtıcıları, NORAD

- Disk tipi düşük verimli Yalıtıcılar

-

Elektrik Bağlantıları

- Nötr topraklama bağlantıları

- 2700 ve 3000 Şasi

- Topraklama grupları

-

Özel Testler/Raporlar

- IBC Sertifikaları

- Jeneratör seti test raporu

- Burulma titreşimi analizi

- 1,0 güç faktöründe PGS test raporu

- 0,8 güç faktöründe PGS test raporu

- Standart motor test şarjı

- Yakıt tüketim testi

- Jeneratör seti tüketim testi

-

Marş / Şarj Sistemi

- Marş motoru kapağı

- Elektrikli çalıştırma motorları

- Hava basıncı regülatörü

- 24 Volt akü seti - Kuru

- Blok suyu ısıtma cihazları

- Motor marş grubu

- 10, 20, 35 ve 50 Amper Akü şarj cihazları

- Havalı marş motorları

-

Genel

- Özel boya renkleri

- US aid amblemi